| Our 103rd Year! |

1-800-328-5689 |

August 2018 • Issue #643 |

|

|

||

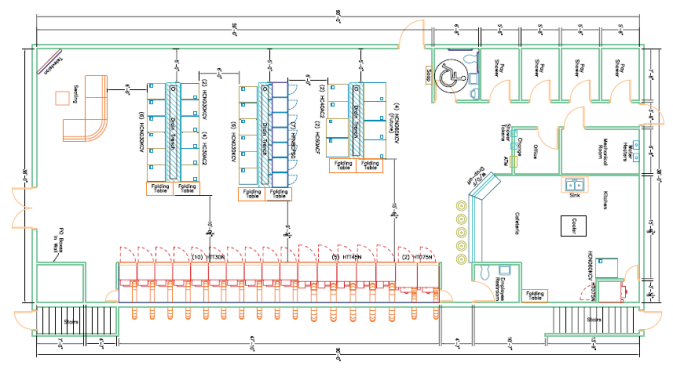

Our CustomersIowa Veterans Home in Marshalltown, IA

IVH Laundry Supervisor Hope Harvey has the task of making sure the laundry of some 500 residents is done right every time. The new building and its state-of-the-art equipment make the job of doing an average of 7,000 pounds a day significantly easier. There are 20 staff, one seamstress and 35 resident workers on her team working in the new 16,500 square foot facility with state-of-the-art machinery. Harvey is a veteran of laundry service work in the public and private sector and is thrilled with the facility and equipment which improve operations, use less energy and water and boost worker morale. The old laundry was in a windowless basement. The new facility has windows and re-cycles clean air. Harvey said there are benefits to the new IVH system. “Our new Continuous Batch Washer (CBW) has five modules and 110-pound capacity of each module,” Harvey said. “It takes an average of six minutes to transfer goods from one module to another. The new CBW uses less energy, less water than our old model. “Our old washers would use 2.7 gallons of water per pound, but with the new pulse-flow tunnel washer that is significantly reduced to .9 gallons per pound. It recovers water from extraction device and premixes it with fresh replenishment water.” Laundry is returned to residents two or three times a week, depending on where a resident lives. The service is free-of-charge. “By whichever means residents have their clothes laundered, it is extremely important that they have all their clothes marked with their name,” Harvey said. “If clothes items are not marked, they could get lost. If not claimed, unmarked clothing is donated to the clothes closet.” Laundry staff work 6 a.m. to 2:30 p.m. Monday to Friday. “It is one of the most popular shifts at IVH,” Harvey said. “We have low staff turn-over.” – Written by Mike Donahey, August 14, 2018. Reprinted with permission

|

|||

| |

|||

|

|||||

| |

|

|

|||

| |

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

| |

|

|

Parts Ideas From BarbDRYER LINT SCREEN SPECIAL – Ask for special when you order in September

It’s that time of year again. The weather turns cold and is unpredictable.

|

|

|

|

|

|

|

Water Conservation for On-Premise Laundries

|

|

|

|

| |

|

| |

|

| |

|||

Calendar of Events:October 3-4 – Midwest Drycleaning Expo - Lake Lawn Resort, Delevan, WI – www.wiscleaners.com June 20-23, 2019 – CLEAN SHOW 2019 Morial Convention Center, New Orleans – Get your hotel now! – www.cleanshow.com

|

|||

|

3750 Dunlap Street North Arden Hills, MN 55112 651-646-7521 Toll-Free: 1-800-328-5689

13636 Carmen Ave, Suite 4 |

Equipment Department Manager: Mike Baker |

Service Engineers: Dan Elstad, Andy Putnam, Lewis Harris, Maurice Lee |

Purchasing / Accts. Payable / Supply Department Manager: Chris Schiefelbein |